If dirty coolant machined better, no one would ever dump it. Removing the tramp oil from the coolant offers dramatically increased tool life, improved parts finish and reduced new coolant purchases.

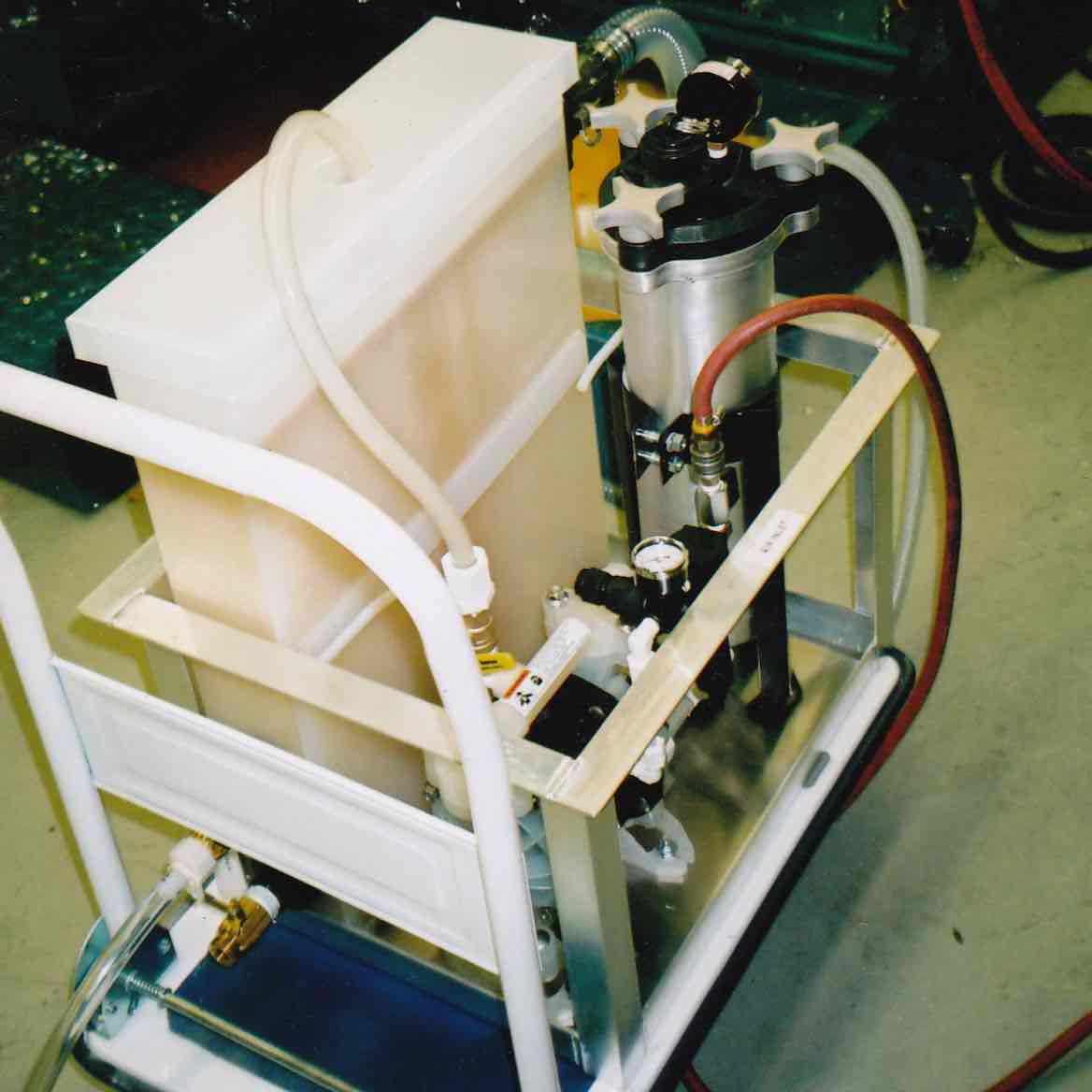

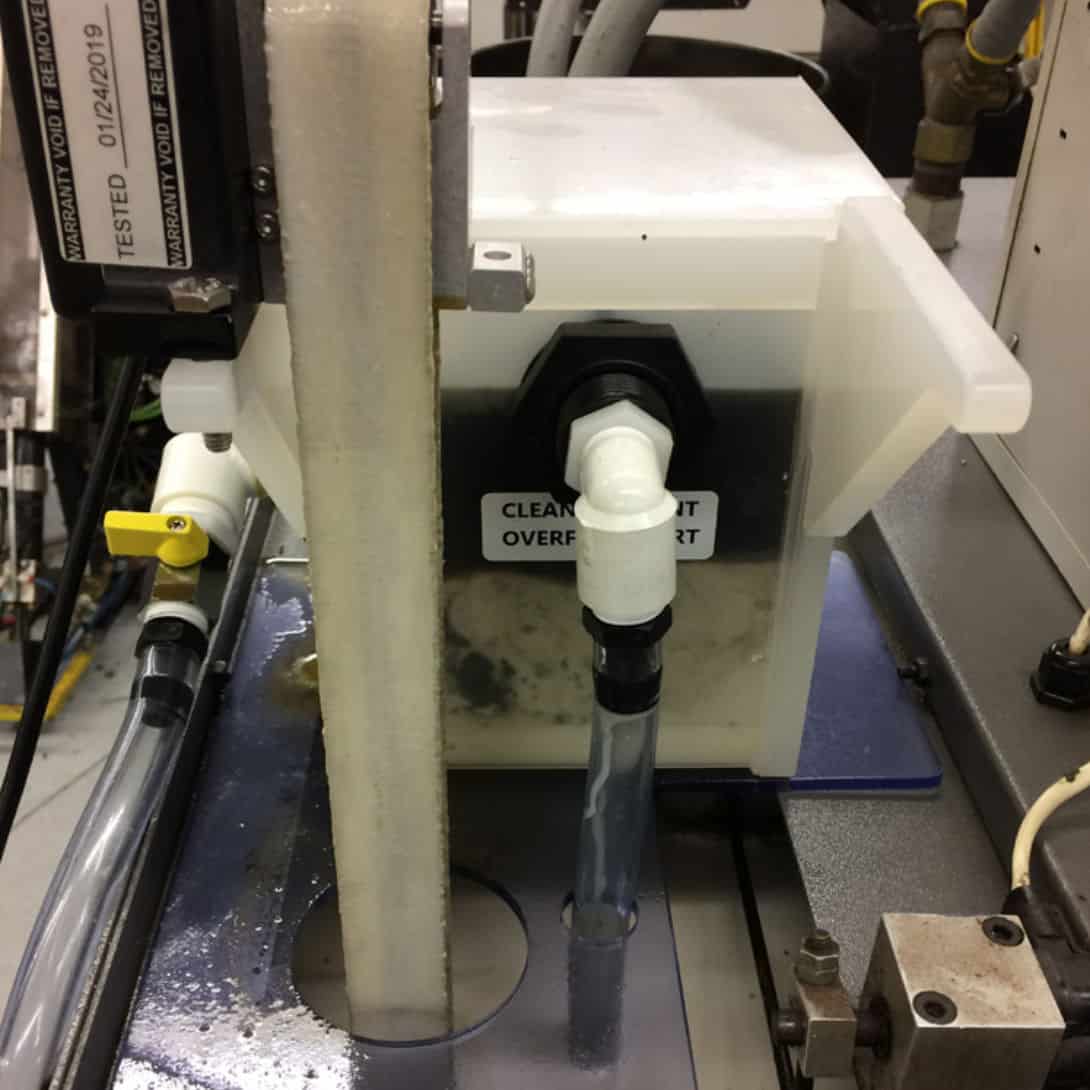

Models range from single to multiple sumps; compressed air to electric driven systems; units that are floor standing, cart mounted, or magnetically mounted to the machine.