Rapidly removes tramp oil. Filters and cleans the entire sump.

TKO Tramp Oil Separators

Advantages:

- Extended tool life, improved parts finish

- Smoke and odor eliminated.

- Multiplied coolant life = Much less machine downtime, greatly reduced coolant purchase

& disposal costs. - Sets up in minutes – Requires minimal operator attention.

Exclusive Keller Features:

- Patented permanent oil separating (coalescing) element, never needs changing.

- Rugged high flow 1/2” air-operated pump provides rapid tramp oil removal, circulates

& aerates entire sump. - Compact inlet device can access any pump.

- Air operated, requires no electrical connections.

Selection and Ordering Information

| Ordering Designation | TKO-6 | TKO-10 | TKO-14 |

|---|---|---|---|

| For Sump Sizes (gallon) | 25-150 | 25-200 | 50-250 |

| Footprint (all models) | 14” x 14” | 14” x 14” | 14” x 14” |

| Height | 24” | 30” | 36” |

| Weight (empty) | 35 lbs. | 37 lbs. | 43 lbs. |

| Compressed air requirements (all models) | 0.5 SCFM @ 20 psig | 0.5 SCFM @ 20 psig | 0.5 SCFM @ 20 psig |

| PRICE | $1695.00 | $1795.00 | $1895.00 |

Accessory Items (All Models)

Price

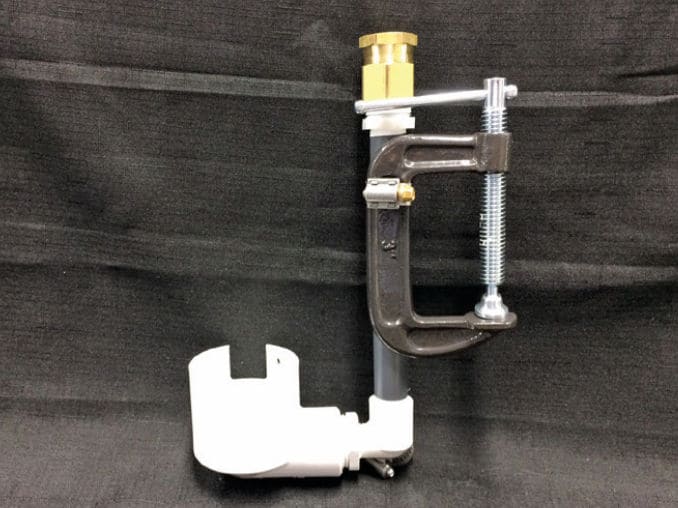

“Cling-On” frame with magnets, to mount TKO-6 to side of machine tool (CLO-2)

Price:

$315.00

Replaceable filter element, 150 micron, 10″ long (R10-3150)

Price:

$6.75 each

Optional Bag Filter, with 5 filter bags (BA-0475-TKO)

Price:

$1,375.00 each

Pack of 5 25 micron filter bags for BA-0475 (RAP-25)

Price:

$45 per pack

Automatic Timer for Untended Operation of TKO Units (TBV-1)

Get these benefits:

- Ideal for shops with limited compressed air supply

- TKO unit can be run untended during off-hours

- Eliminates operator involvement in daily TKO operation

Features Include:

- Built-in 7-day programmable timer

- Easy to program

- Multiple cycles possible each day

- Lithium battery protects program for five years

- Large LCD display

How the Automatic Timer Valve Works

The Keller TBV-1 automatic timer ball valve, mounted on the compressed air supply to a TKO dedicated sump cleaner, will open and close the compressed air supply for a selected duration on a programmable schedule. With the TBV-1 valve, the TKO unit can be operated and shut down periodically with no operator attention.

Price:

$701.00

Photo Gallery

Click for full size image

More Information

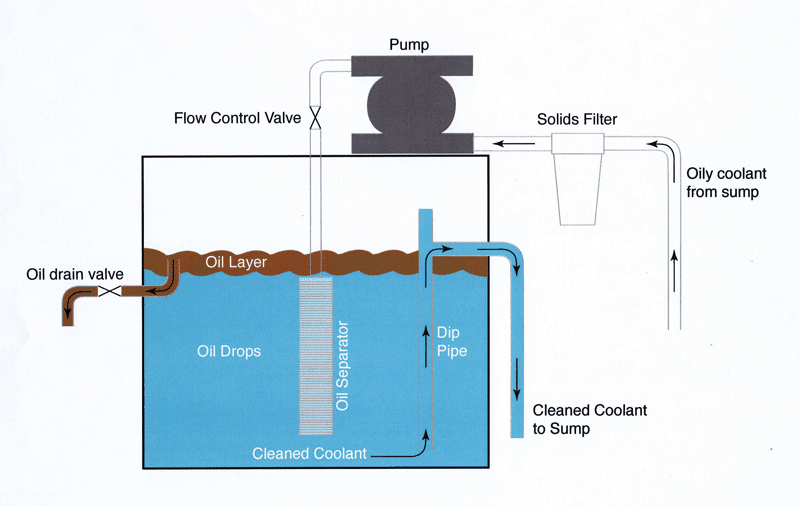

How It Works

The self-priming air operated pump pulls the tramp oil/coolant mixture from the surface of the sump through the floating inlet device, then through a cartridge filter which removes any chips from the fluid. The oil/coolant mixture is then pumped through the patented Keller all-plastic separator element immersed in a separator tank. The cleaned coolant continuously returns to the sump. The oil layer collects on the top of the separator tank and is occasionally drained into a waste oil container, simply by opening the oil drain valve. To clean the Keller patented coalescing pack, simply unthread the disc pack from the coupling and wash. Then re-assemble.