Whether you are using a water-based or an oil-based coolant system, coolant filtration is essential to maintain industrial machinery. Keller’s coolant filtration products remove sludge and chips from coolant sumps – including particles as small as 1 micron in size. Specific designs can handle pressures up to 300 psi.

Coolant Filtration Products

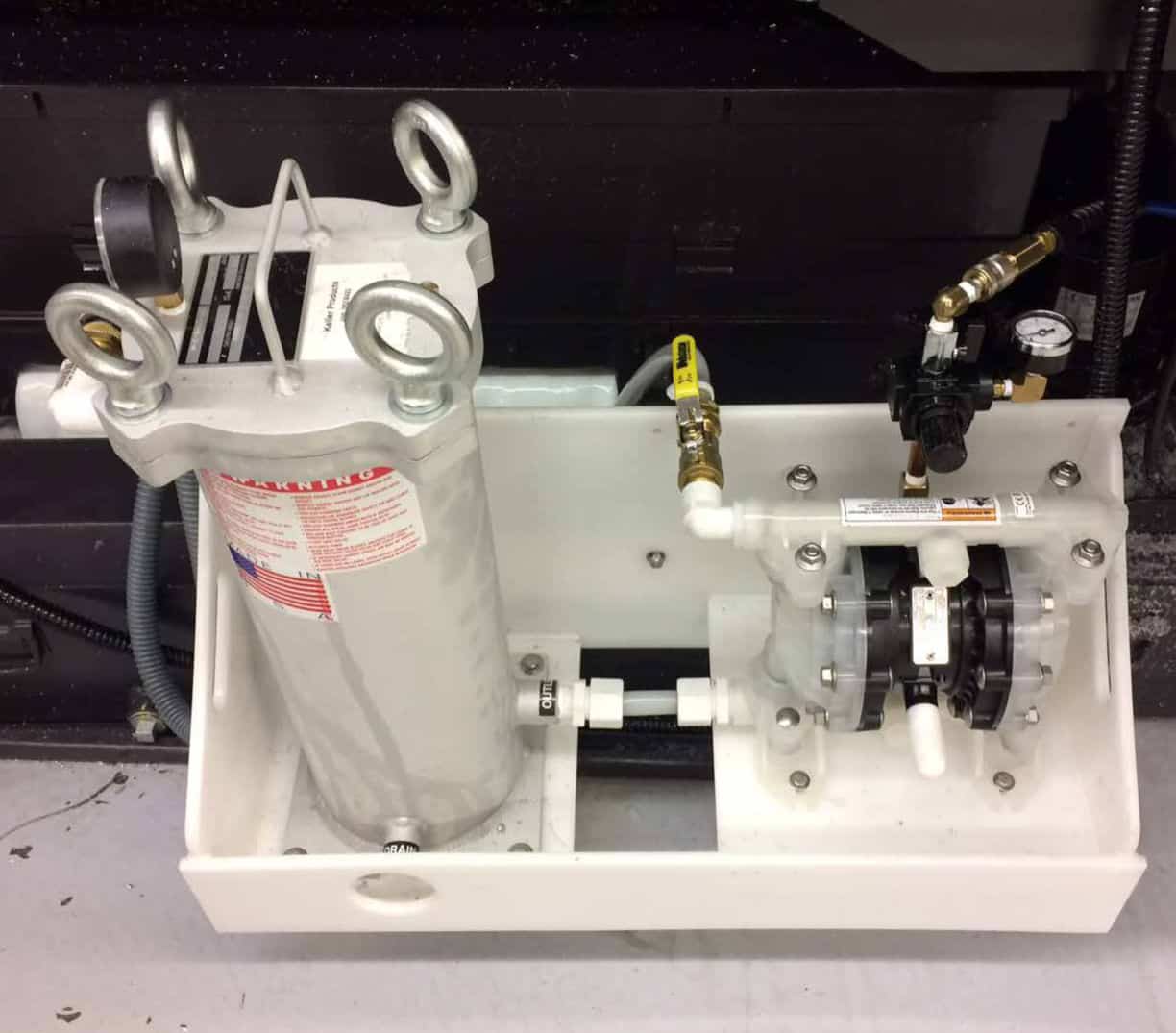

Portable Pump/Filter Unit

Portable pump/filter systems can remove both floating and settled chips and fines from coolant or oil. Flow rates as high as 20 GPM, and filtration down to 1 Micron.

More Info

Keeping Solids Level Low in Sumps:

- Greatly increases tool life, minimizes tool breaking due to dirty fluid

- Eliminates parts finish problems

- Reduces burden on high pressure filter

- Minimizes downtime and labor for manually cleaning sumps

The Unit:

- Pulls from sump and continuously returns filtered fluid to the sump at high flow rate

- No need to pump out sump or shovel solids

- Cleans a typical sump in minutes, then can easily be moved to the next sump

- Portable unit keeps multiple sumps clean

- Also filters and recycles fluid from chip spinners or chip compactors

- Air-operated––No electricals––Inherently fireproof

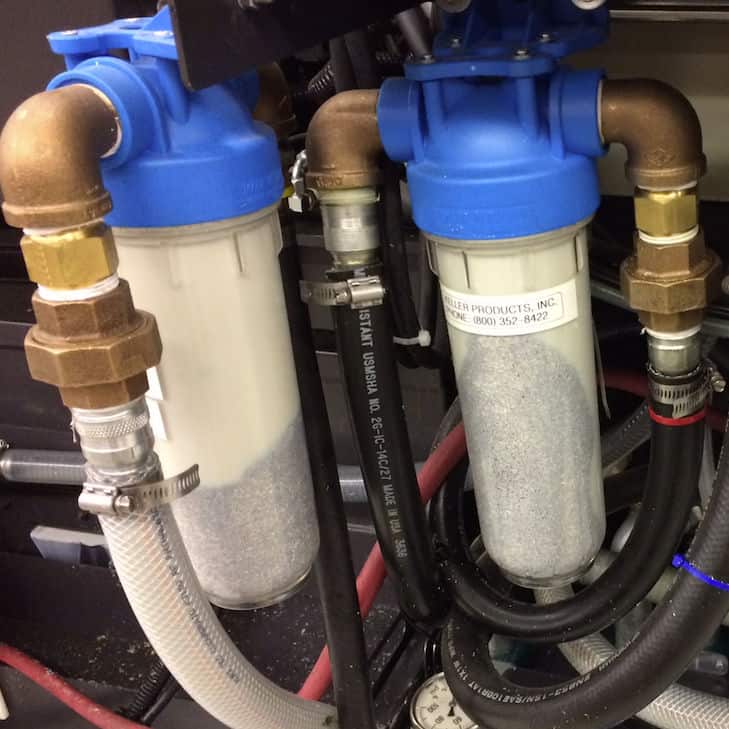

In-Line Coolant Filters

Economical Inline Coolant Filters: Proprietary cleanable filter design for removing chips from coolant supply lines. Filter assemblies rated up to 300 PSIG.

More Info

Benefits:

- In-line filters protect to-the-spindle, through-the-spindle and through-the-tool coolant systems, preventing tool breakage & machine shutdowns

- Keller permanent cleanable filter elements never need replacement

- Keller filters are easily installed in-shop in the coolant lines

Exclusive Features

- High flow rate–One 10″ element can handle 25 gpm

- Keller permanent filter elements have superior solids holding capacity, far better than screens or disposable filters.

- Available with stainless steel housings rated at 300 psig

- Compact design, easy to install on any machine

- Inexpensive to purchase, no replaceable parts

- Ideal for shops, machine tool distributors & OEMs

In-Line Bag Filters

Inline Bag Filters: Remove chips and fine particles as small as 1 micron from coolant or cutting oils. Ideal for protecting cutting tools and spindles.

More Info

Benefits:

- In-line bag filters protect to-the-spindle, through-the-spindle and through-the-tool coolant systems, preventing tool breakage & machine shutdowns

- Cleaning cutting oil or coolant greatly extends tool life

- Keller bag filters are easily installed in-shop in the oil or coolant lines

- Low cost, long life filter bags are easily replaced in a couple of minutes

Keller bag filter housings with felted polyester bags provide excellent solids holding capacity to ensure uninterrupted runs. Filter bags are easily changed without tools in a couple of minutes. The economical filter bags are available in ratings from 1 micron to 100 microns at the same prices. 25 micron bags are supplied as standard, or the customer may specify a different micron rating. The filter housings, available in 3/4″ and 1-1/2″ pipe sizes, are easily shop-installed downstream from the oil or coolant pump. Maximum operating pressure is 300 psig.

Dedicated Filtration Systems

Keller’s Dedicated Filtration Systems eliminate costly downtime due to plugging coolant lines and machine sump clean-outs and protect expensive machine parts and tooling by keeping the coolant filtered continuously.

Washable Water Filters

Filters with permanent, washable elements clean even the dirtiest water supplies.

More Info

If dirty coolant machined better, no one would ever dump it. Removing the tramp oil from the coolant offers these BENEFITS:

- A quick wash restores the filter element to new condition

- Permanent elements quickly pay for themselves through savings in replacement cartridge costs

- No inventory of replacement cartridges needed

- Eliminate the problem and expense of disposing of contaminated filter cartridges

- Fit the permanent elements in your existing standard 5″, 10″, & 20″ filter housings without modification, or order from Keller’s complete line of filter assemblies

Keller Products units set the industry standard for offering the best value in the market. Our combination of durability, performance, and cost is unrivaled. Keller units have these distinct FEATURES:

- Filter Assemblies from 3/8″ to 2″ Lines Sizes Available

- Filtration as fine as 300 mesh (50 micron)

- Long life between washings because of the depth-filter characteristics of the unique stacked-disc design

- Excellent performance with slimy solids and algae, as well as with granular solids

- Flow rates to 150 GPM

- Immediate shipment from stock

Economical Washable Water Filters

Keller’s newest washable additions are all screen style elements. There are some economical options in the plastic screen designs. These are also capable of being used in drinking water applications. For more industrial style applications, including filtering metalworking fluids, the stainless mesh filters are a good choice. These are offered in two options, a straight cylindrical screen design, or a pleated element which provides greater surface area.

Additional Information:

Why Are Coolant Filtration Systems Necessary?

Machine parts that are being cooled are exposed directly to the coolant. Any contaminants that have been introduced to the coolant can cause damage. Sludge and chips can jam the mechanics; even tiny particles can cause damage that can result in increased wear-and-tear.

Keller’s Exceptional Solutions to Coolant Filtration

Industrial fluid filtration is essential if you are running any kind of manufacturing operation. Keller has various coolant filtration products such as bag filters and convenient portable filter carts. These coolant filtration products will remove even the tiniest particles from coolant. Benefits include:

- Minimizing downtime and maintenance of your equipment

- Increasing tool life and improving part finishes

- Saving on new coolant purchases and disposal costs.

Whatever machinery your company is operating, Keller has a coolant filtration product to meet your needs:

- Portable pump/filter systems filter chips and sludge from coolant or cutting oil. Recycling applications include machine sumps, chip spinners, or chip compactors. With a maximum flow of 20 GPM, the Keller portable pump/filter can clean a sump in minutes.

- Inline bag filters remove chips and fine particles as small as 1 micron from coolant or cutting oil. They extend tool life and prevent damage that causes machine downtime.

- Inline filtration equipment with permanent elements prevents plugging of coolant delivery systems.

- Washable water filters provide superior filtration of even the dirtiest water, with permanent filters that can be easily removed and cleaned to eliminate the costs of buying replacement filters.

- Oily wastewater systems remove oil and other contaminants from industrial wastewater (both suspended and dissolved) to allow for environmentally friendly disposal.

Click on one of the images above for further information, model information and specifications on Keller coolant filtration products.