Rapidly removes tramp oil. Filters and cleans the entire sump.

SST Dedicated Tramp Oil Separators

Advantages:

- Extended tool life, improved parts finish

- Smoke and odor eliminated

- Multiplied coolant life = Much less machine downtime, greatly reduced coolant purchase & disposal costs

- Sets up in minutes – Requires minimal operator attention.

Exclusive Keller Features:

- Patented permanent oil separating (coalescing) element, never needs changing

- Rugged high flow 1/2” air-operated pump provides rapid tramp oil removal, circulates & aerates entire sump

- Compact inlet device can access any pump

- Air operated, requires no electrical connections

- New stainless steel tank for added durability

How the SST Pump/Skimmer Works

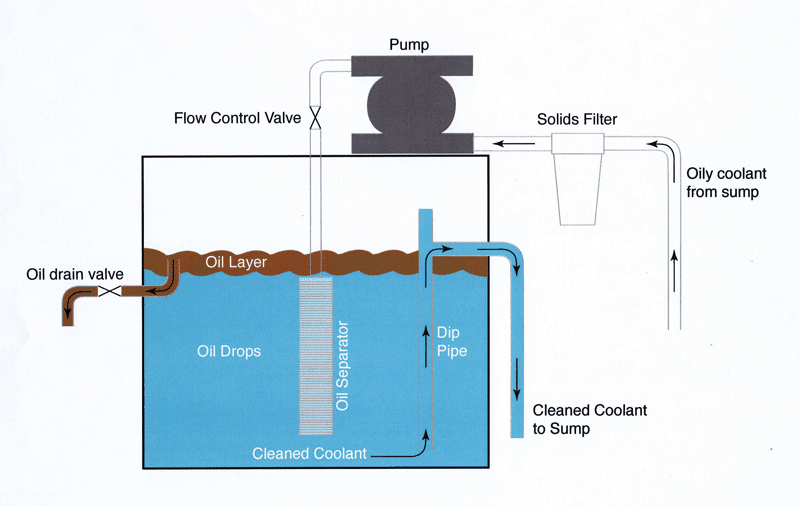

The self-priming air operated pump pulls the tramp oil/ coolant mixture from the surface of the sump through the floating inlet device, then through a cartridge filter which removes any chips from the fluid. The oil/coolant mixture is then pumped through the patented Keller all-plastic separator element immersed in a separator tank. The cleaned coolant continuously returns to the sump. The oil layer collects on the top of the separator tank and is occasionally drained into a waste oil container, simply by opening the oil drain valve. No other operator attention is required.

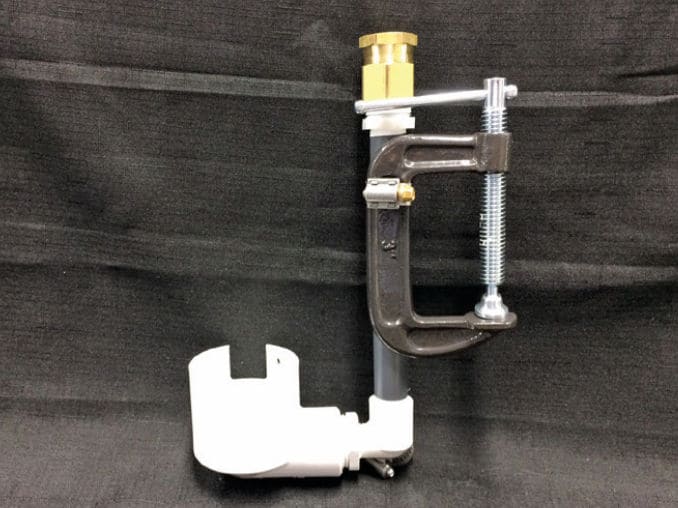

Three models of SST Separators are offered, to satisfy any sump size. Each SST Separator is shipped by UPS complete, ready for setup. The customer supplies only a 1/4” compressed air line. The unit may be set on the floor adjacent to the sump, or mounted on the machine tool using the CLO-1 magnetic frame (see photo).

Selection and Ordering Information

| Ordering Designation | SST-6 | SST-10 | SST-14 |

|---|---|---|---|

| For Sump Sizes (gallon) | 25-150 | 25-200 | 50-250 |

| Footprint (all models) | 14” x 14” | 14” x 14” | 14” x 14” |

| Height | 24” | 30” | 36” |

| Weight (empty) | 29 lbs. | 32 lbs. | 35 lbs. |

| Compressed air requirements (all models) | 0.5 SCFM @ 20 psig | 0.5 SCFM @ 20 psig | 0.5 SCFM @ 20 psig |

| PRICE | $2795.00 | $2895.00 | $2995.00 |

Accessory Items (All Models)

| CLO-2 | “Cling-On” frame with 6 magnets, to mount SST-6 to side of machine tool | $295.00 |

| R10-3150 | Replaceable filter element, 150 micron, 10” long | $6.25 |

| BA-0475-TKO | Optional bag filter assembly | $1195.00 |

| RAP-25 | Pack of 5 25-micron filter bags for BA-0475-TKO | $40.00 |

More Information

How It Works

The self-priming air operated pump pulls the tramp oil/coolant mixture from the surface of the sump through the floating inlet device, then through a cartridge filter which removes any chips from the fluid. The oil/coolant mixture is then pumped through the patented Keller all-plastic separator element immersed in a separator tank. The cleaned coolant continuously returns to the sump. The oil layer collects on the top of the separator tank and is occasionally drained into a waste oil container, simply by opening the oil drain valve. To clean the Keller patented coalescing pack, simply unthread the disc pack from the coupling and wash. Then re-assemble.