A Keller Portable Tramp Oil Separator Rapidly Removes Oil, Cleans, Aerates, and Filters Entire Sump

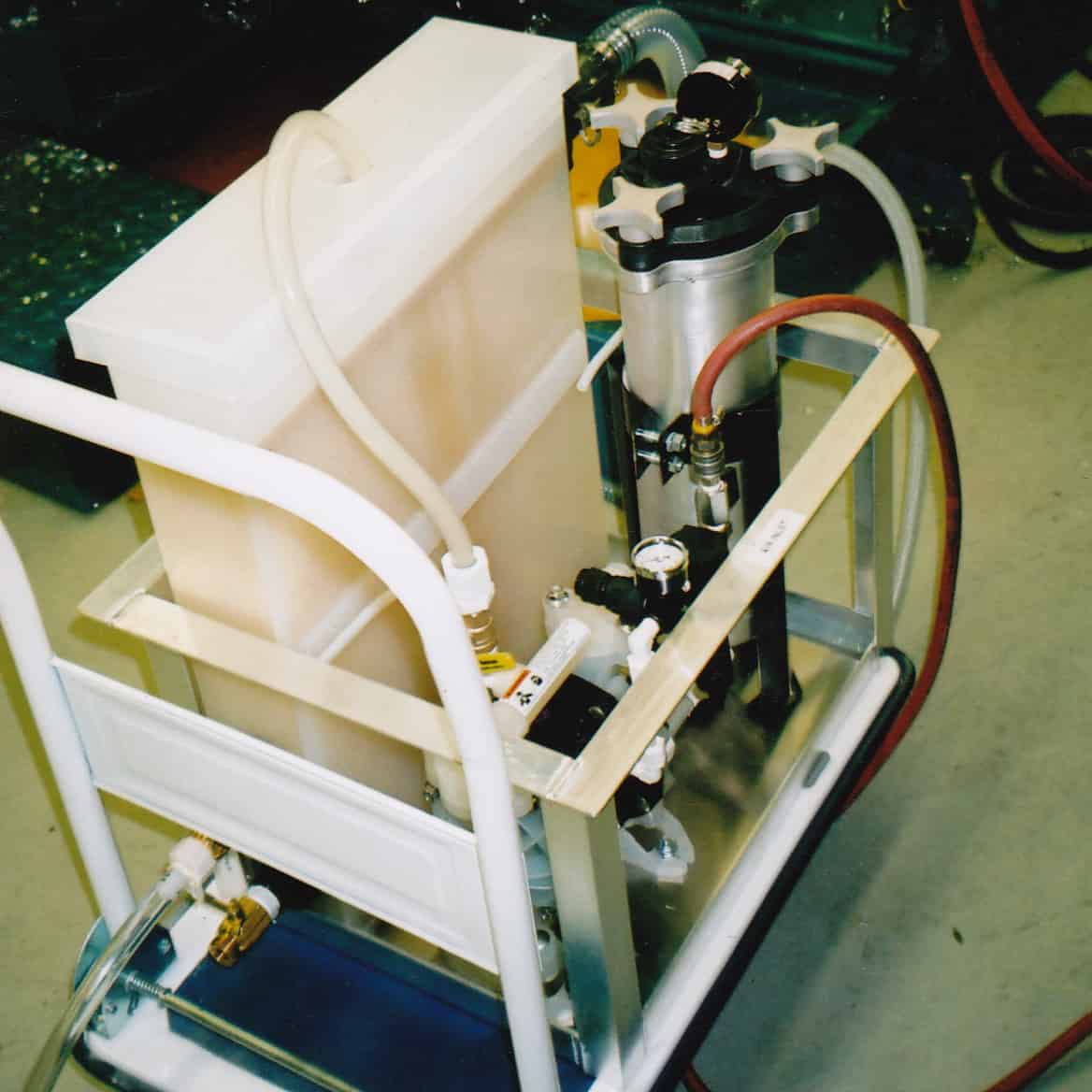

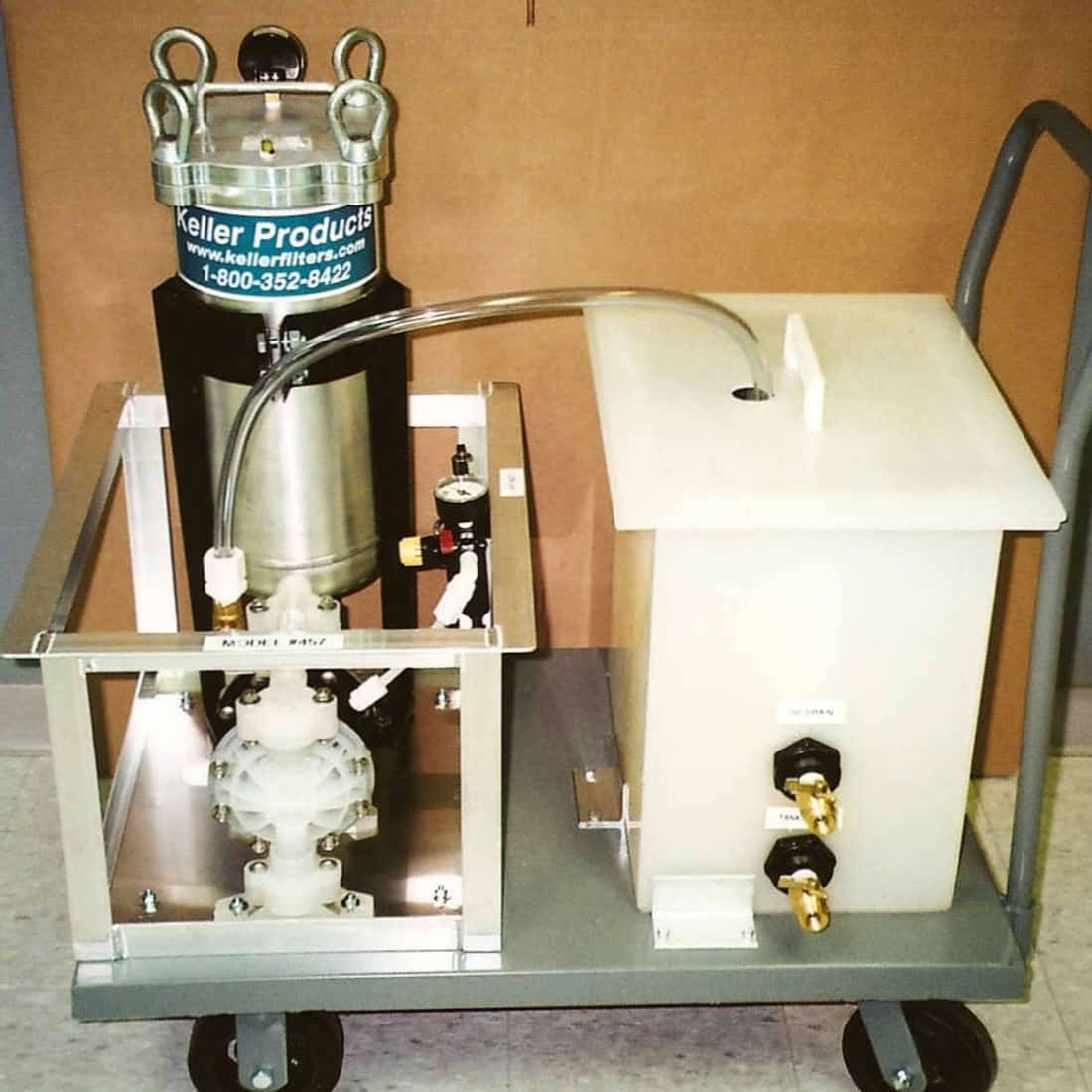

Portable Tramp Oil Units

Advantages:

- Patented permanent oil separating (coalescing) element.

- Rugged high flow 1/2” air-operated pump.

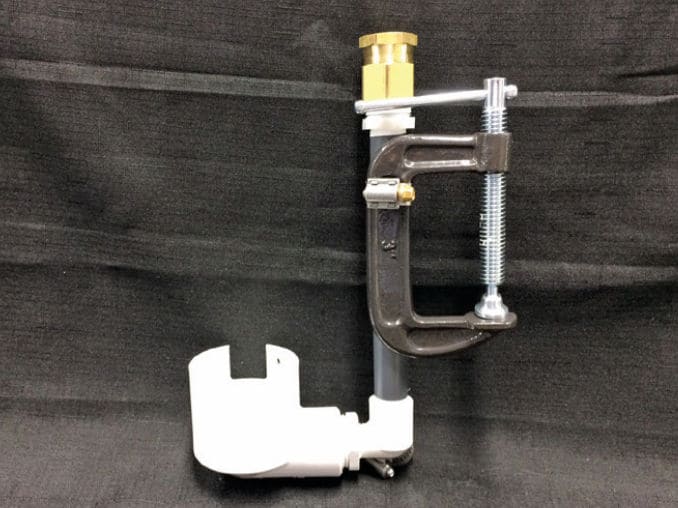

- Compact inlet devices can access any sump.

- No electricals – simply connect 1/4” compressed air line.

- Sets up in minutes.

- Bag filter housing standard on all units.

Applications:

- Extended tool life, improved parts finish.

- Smoke and odor eliminated.

- Multiplied coolant life.

- Greatly reduced coolant purchase & disposal costs.

- Extremely cost effective per sump.

How the Keller Separators Work

The self-priming air operated pump pulls the tramp oil/coolant mixture from the surface of the sump through the floating inlet device, then through the bag filter which removes any chips from the fluid. The oil/coolant mixture is then pumped through the patented Keller all-plastic separator element immersed in a separator tank. The cleaned coolant continuously returns to the sump. The oil layer collects on the top of the separator tank and is occasionally drained into a waste oil container, simply by opening the oil drain valve. No other operator attention is required.

Keller offers four portable models of Tramp Oil Separators to satisfy any machine shop requirement. Each portable separator can ship via UPS. Once assembled, the customer supplies only a 1/4” compressed air line to operate the unit.

A Keller portable separator can clean a sump in 3 to 4 hours, and then may be moved to another sump and set up in minutes. We recommend that each sump be cleaned once per week. A separator can clean two sumps in a single shift, or 10 sumps per week in a one shift 5 day operation. The machine tool may be operated while the Tramp Oil Separator is operating.

Selection and Ordering Information

| Ordering Designation | #315 | #365 | #457 | #465 |

|---|---|---|---|---|

| Sump Size Ranges (gallons) | 40 – 400 | 40 – 400 | 60 – 1000 | 100 – 2000 |

| Oil Collected Prior to Draining (gallons) | 4 | 4 | 10 | 14 |

| Volume of Full Bag Filter (gallons) | 0.5 | 2.5 | 2.5 | 2.5 |

| Dimensions (L x W) | 30” x 20” | 30” x 20” | 38” x 24” | 38” x 24” |

| Two Sump Inlet Devices Provided | RSM-3 | RSM-3 | RSM-3 | RSM-3 |

| Size of Oil Separator Tank (gallons) | 10 | 10 | 15 | 25 |

| Type of Prefilter | Small Bag | Medium Bag | Medium Bag | Medium Bag |

| Unit Weight Empty | 80 lbs | 115 lbs | 140 lbs | 150 lbs |

| Compressed Air Requirements @ 20 PSI | 1.0 SCFM | 1.0 SCFM | 1.0 SCFM | 1.0 SCFM |

| PRICE | $4,595.00 | $4,995.00 | $5,695.00 | $5,995.00 |

Note: 5 Filter Bags supplied standard with each unit

Replacement Filter Bags

| RAP-25* – 25 Micron Filters, Pack of 5 bags for #315 | $45.00 / Box of 5 |

| RBP-25* – 25 Micron Filters, Pack of 5 bags for #365, #457, #465 | $45.00 / Box of 5 |

*25 micron bags supplied unless otherwise specified. Also available: 100, 50 10, 5 and 1 micron